Unique Surface Finishes

Elevating Aesthetics with Distinctive Surface Textures

“Hot Stamping” is an in-line process that adheres a thin layer of laminate to the profile with the help of heat and pressure. Hundreds of finishes are available as stock products for your convenience.

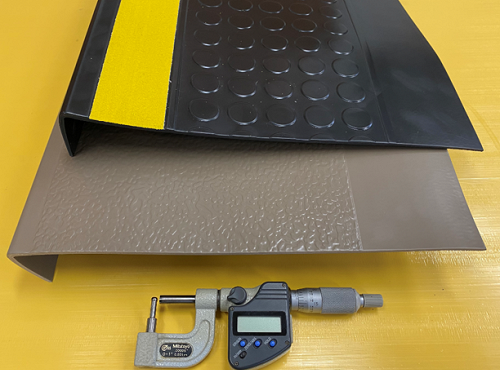

Embossing is an in-line process that creates a deep texture to extruded parts. A high-pressure textured roller impregnates the texture while the polymer is in its molten state.

Wisconsin Plastic Products, a Pexco Company, uses its “Spattercoat” process to achieve an appealing texture to extrusions

Wisconsin Plastic Products, a Pexco Company, uses its “Hot Stamping” process to achieve aesthetics shockingly close to stained wood and brushed metals

Wisconsin Plastic Products, a Pexco Company, based in Plymouth, Wisconsin, uses In-line embossing technology to create deep textures within extruded products, serving manufacturing partners in Minneapolis, MN, and Chicago, IL.