Celuka Foam Technology

Advanced Foam Engineering for Superior Performance

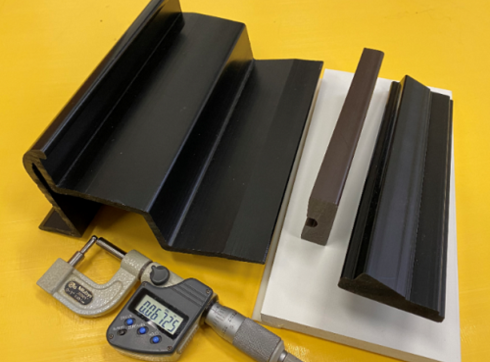

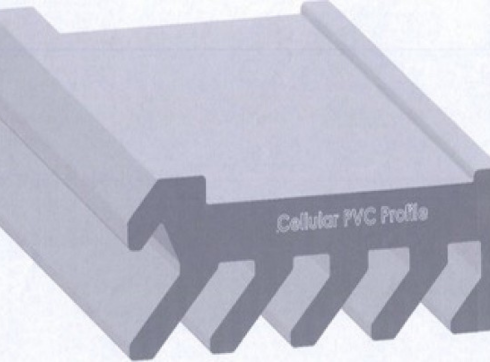

Celuka is an inward foaming process used to extrude components with reduced density. The Celuka process suppresses cell formation at the surface creating a hard high-quality finish while allowing the hot melt to expand inward forming a cellular structure. The hard outer skin and fused inner core create a strong profile with multiple post finish options, fastener retention as good as wood, and excellent insulation properties.

Celuka foam technology can reduce the weight of your product by up to 50%!

Celuka foam technology excels in thick wall applications

Products made with the celuka foam process can be painted and easily machined

The Celuka foam process creates an exceptional exterior surface finish

Celuka foam technology offers the tightest dimensional and shape control compared to competing foam processes