Celuka Foam Solution

Wisconsin Plastic Products, a Pexco Company, uses the Celuka foaming process coupled with chrome hot-stamping to bring an innovative window treatment to market.

The Problem:

The Plan of Attack:

PLAN DEFINITION

Wisconsin Plastic Products, a Pexco Company, proposes the Celuka foaming process coupled with in-line hot stamping as a solution.

EXECUTION

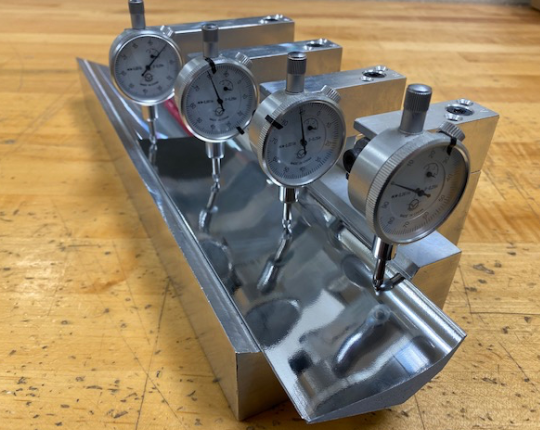

Wisconsin Plastic Products, a Pexco Company, expedites an in-house tooling build requiring ten Celuka style vacuum calibrators, dual head hot stamper, custom gaging, and fully streamlined Celuka extrusion die. Three days into product development trials, the team landed data that proved rock-solid process capability for the critical reflectance curve. The final challenge was chrome hot-stamping opposing surfaces without jeopardizing the stability of the reflectance curve. After two generations of hot stamp application rollers, the team achieved the mirror reflectance and maintained the critical curve!

The Solution

SUCCESSFUL PRODUCT LAUNCH

EXCEPTIONAL DIMENSIONAL CONTROL

EXPEDITED RESULTS

STRENGTH IN PRODUCT ENGINEERING

IN-HOUSE CUSTOM EQUIPMENT BUILD