- Vacuum Calibration yields higher line rate compared to competing technology

- Vacuum Calibration is repeatable science based technology

- Vacuum Calibration can handle tolerances as tight as +/-.005”

- Vacuum Calibration eliminates sink marks

- Vacuum Calibration produces products with exceptional surface finish

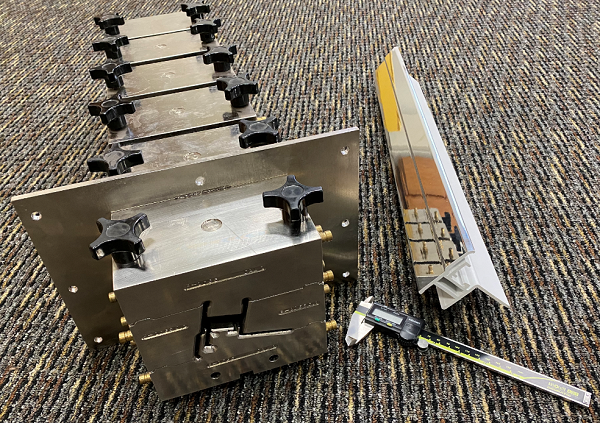

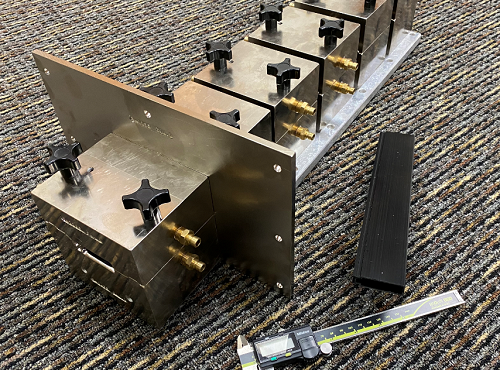

Our vacuum calibration system is able to manufacture your product to exact dimensions! After the plastic exits the extrusion die, it enters a series of calibration blocks where vacuum is applied drawing the material against the walls of the calibrator. The polymer is cooled and solidified while inside of the vacuum calibrator insuring tight dimensional control. Vacuum calibration offers excellent dimensional stability and shape consistency from part-to-part and run-to-run.

Polymers Processed with Vacuum Calibration

RPVC Rigid Vinyl

FPVC Flexible Vinyl

HIPS High Impact Polystyrene

ABS Acrylonitrile Butadiene Styrene

Acrylic

Polycarbonate

PP Polypropylene

PE Polyethylene

Thermoplastic Elastometer

PVC Cellular

ABS 10% & 20% Glass Reinforced ABS

Co-Polyester

PCABS Polycarbonate ABS

TPU Thermoplastic Urethane